Crack isolation and sound control products are designed to solve well-known issues in flooring installation. Crack isolation products keep subfloor cracks from transferring into tile and stone floors. Sound control products are designed to minimize impact noise from footfalls and other types of traffic, as measured by their Impact Insulation Class (IIC) rating. We asked contractors and manufacturers to share their insights into these different products.

Flooring Installation: Crack isolation

James Woelfel, president of the National Tile Contractors Association and vice president of Artcraft Granite, Marble and Tile Co. in Mesa, Ariz., said he uses crack isolation products on every job. These are dependable products when used correctly, but become a problem when they’re not properly applied, he stated.

“The theory behind crack isolation is to transfer cracks from the substrate to the weakest point in the installation, which is usually the grout joint. The biggest error I see is people not using a wide enough membrane for spot applications. They’ll have an 18″ by 18″ tile that will be going over a hairline crack, and so they just put down an 18″ by 18″ or 18″ by 36″ membrane. The problem is, for the membrane to work it needs to be three times the width of the tile. Otherwise you’re not transferring the crack to the grout joint-you’re transferring it to the tile itself.”

Another issue is putting down crack isolation for no reason, which is often indicative of a mindset that will lead to other problems in the installation. “Crack isolation is a wonderful product, and it has absolutely furthered our industry. But if people are not familiar with how to use it, they end us causing themselves more problems than the product can solve.”

Woelfel added, “People often misconstrue crack isolation as a type of movement joint, so they think they’re not going to need any movement joints. That is completely wrong. You will always need movement joints.”

Dan Kelley of Kelley Tile and Marble in Canyon Lake, Calif., offered his expertise to help Merkrete develop its Fracture Guard FD, a fast-drying, liquid-applied crack isolation membrane.

“I’ve used Merkete products for years, back when they had the [Fracture Guard] 5000. After they came out with the 7000 I told them we needed something that dries quicker. I brought 10 guys down with me to their office in Orange County, and they listened to the installers telling them what they wanted. Often when you sit down with a company, they’ll have a meeting with you but not take any action. Merkrete not only listened to what we wanted-they developed it and it’s a good product.”

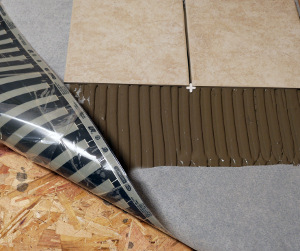

Al diBicarri of AD Ceramic Tile in Marlborough, N.H., swears by Schluter’s Ditra uncoupling mat. “We usually do a lot of high-end residential work, and we use Ditra matting on every job. I like it because it’s a lot simpler for me to use than a cement board product, and it has the added advantage of the uncoupling benefit. We also use the Ditra-Heat mat so we can install radiant heating cables easily.”

He said working with Ditra is simple, provided the installer takes the time to read the directions. “A common mistake installers might make is not making the thin-set loose enough or not having the right sized trowel for the job. I’ve been doing this for 40 years now, so I think it’s pretty easy.”

He added, “Schluter is a great company for technical support, and there’s plenty of literature and always someone to talk to. But really it comes down to having common sense. When you put down the mat, pick it up by an edge and make sure it has 100 percent contact with the thin-set.”

Alan Pratt of Set in Stone in Parkman, Maine-who uses Schluter Ditra in his projects-also praises its ease of use. “I can teach someone how to put Ditra down in 10 minutes. It makes jobs go faster for us. Ditra is light, easy to work with, you don’t have to cut it with a power tool and it’s user-friendly.”

Melanie Debelak, Keene Building Products marketing manager, had this to say about the company’s KeedeRoll 100 Uncoupling Mat: “KeedeRoll 100 is designed for use with both modified and unmodified mortars. It works by absorbing subfloor movement and reinforcing the mortar, protecting the tile from shear stresses. It can be used over plywood or OSB subfloors, Dependable patches and self-levelers, concrete slabs and with radiant heat flooring.”

Sound control products

Jim Wink, Foam Products Corp. vice president of sales and marketing, stated, “Our underlayments are used daily in residential and commercial flooring wood, laminate and LVT/LVP installations for acoustical sound control. For the past 15 years, our acoustical Eco Silencer underlayments have been used for wood and laminates and for more than four years, our acoustical Silencer LVT underlayment has been used for vinyl plank flooring.”

Jack Boesch, MP Global Products director of marketing, noted, “Our new SoundBuffer universal acoustical underlayment is made from 100% virgin latex rubber. It can be floated, single-glued or doubled-glued, nailed down or stapled, and is suitable for luxury vinyl, laminate, and engineered and solid wood floors.”

Original Article: Floor Covering Installer – Michael Chmielecki – May 16, 2016

Posted on: Wednesday, May 25, 2016

Last modified on: Wednesday, May 25, 2016

Join Our Newsletter

You are about to install your new flooring. As you lay the first plank you realize that